Particulates

In layman's terms particulates are dust. They're little particles suspended in the air. You'll also hear this term when it comes down to the cleanliness of your oil. The oil filter in your car is used to trap the particulates that get into the oil. In the same way, you often need to trap that particulates in your compressed air.

Particulates, and the filters that trap them, are measured in microns. A micron is another word for micrometer, which is one millionth of a meter.

Particulates, and the filters that trap them, are measured in microns. A micron is another word for micrometer, which is one millionth of a meter. To the right you can see a perspective on how small a micron is. Human hair is 50-70 microns wide. When we talk about filtering out particulates in compressed air, we start out at "big" particles, which are 3-5 microns. Filtration down to .01 micron is common. Special applications can often demand filtration beyond that.

Think of how small that is. A human hair is 50-70 microns, basic filtration traps particles 20 times smaller than that, and common advanced filtration can trap particles that are 5000 to 7000 times smaller than with width of your hair, or 9000 times smaller than a typical grain of sand. The largest particle a human eye can see is in the range of 40 to 50 microns.

Just in the air around us there are thousands of different types of particulates suspended in the air. In industry, there are many other contaminates as a byproduct of what the company does. Obvious examples are sawdust in a cabinet shop, concrete dust at a concrete plant, or grain dust at a mill. However, there are much smaller particles that you can't see in high concentrations, and there are too many to list here.

Just in the air around us there are thousands of different types of particulates suspended in the air. In industry, there are many other contaminates as a byproduct of what the company does. Obvious examples are sawdust in a cabinet shop, concrete dust at a concrete plant, or grain dust at a mill. However, there are much smaller particles that you can't see in high concentrations, and there are too many to list here. The first line of defense against particulates is your compressor's inlet air filter. Many of the things we have mentioned will mess up your compressor if allowed to continually get in. Most compressor inlet filters will be between 1 and 25 microns. The manufacturer will put on the air filter that they think will protect the compressor. Make sure you check in often and keep it clean.

The first line of defense against particulates is your compressor's inlet air filter. Many of the things we have mentioned will mess up your compressor if allowed to continually get in. Most compressor inlet filters will be between 1 and 25 microns. The manufacturer will put on the air filter that they think will protect the compressor. Make sure you check in often and keep it clean.

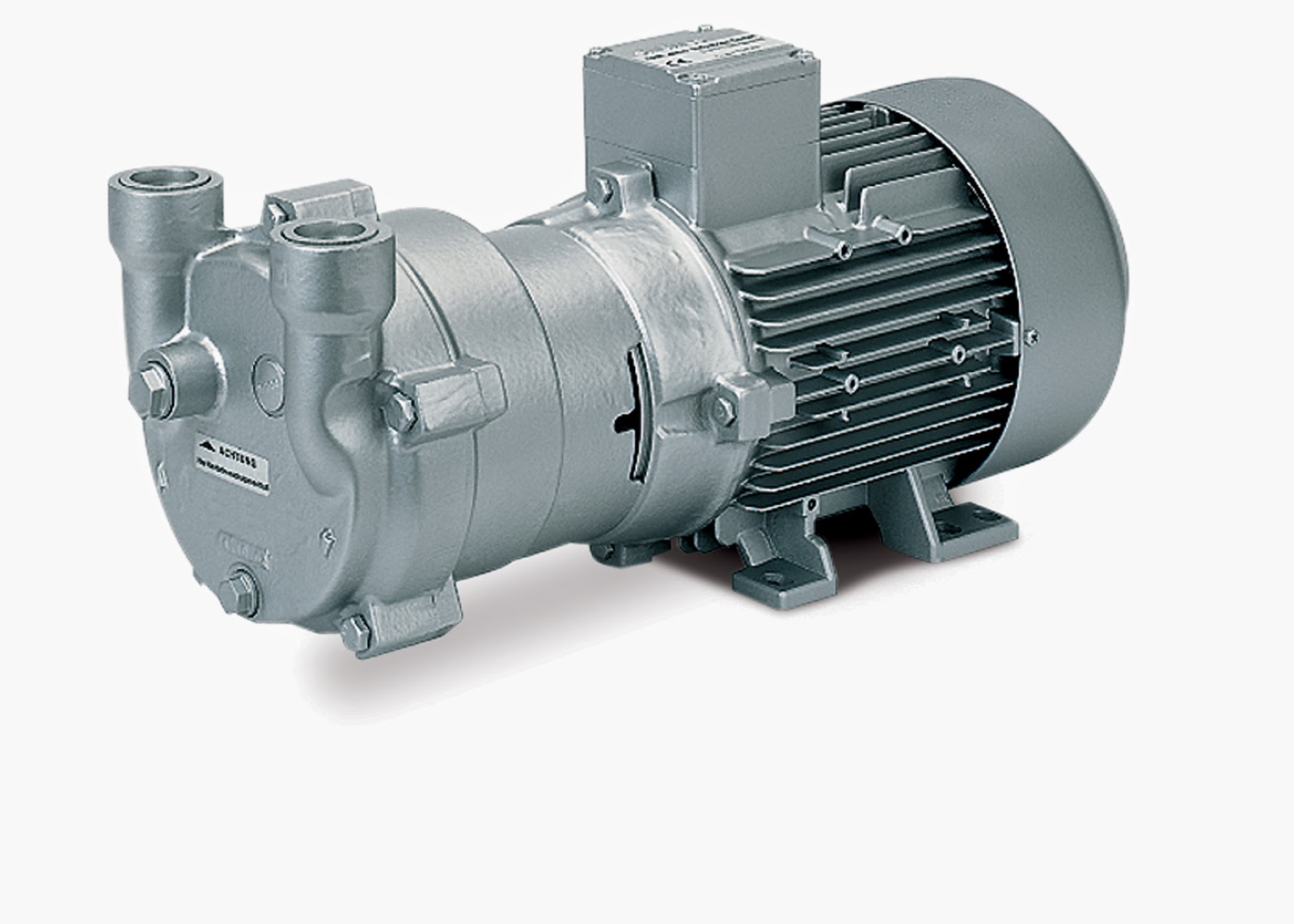

The second line of defense is lubricant. The oil in your compressor (assuming it's oil-lubricated) will trap a large amount of particulates. If your compressor has an oil filter, then many of these will get trapped in oil filter. Again it's important that you keep your oil (and oil filter if applicable) changed on a regular basis.

Filters are the last line of defense for particulates. When talking about particulates, filters will have a micron rating. That will tell you what size particles it traps. If you have a 5 micron filter, then it will trap a large majority of particles 5 microns and above, usually around 99% or greater. The filter may also have a ppm rating, and that tells you how many parts per million of particles of that size (the micron rating) or greater will pass though the filter. Filters have changeable elements inside of them. You need to change them on a regular basis as part of your maintenance plan. For the most part you need to change them every 6 months to a year, depending on how many hours you run per year.

Vapors & Mists

Particulates are solid particles suspended in the air, but there are also vapors and mists suspended in the air around us. Most of it is water, which we discussed last week, but that's not all.

Particulates are solid particles suspended in the air, but there are also vapors and mists suspended in the air around us. Most of it is water, which we discussed last week, but that's not all. A mist is liquid suspended in the air. A vapor is a gas mixed in with the air. Whether a substance will be a particle, mist or a vapor is determined by pressure and temperature of the air it's in. Every substance has a pressure and temperature thresholds where it changes states.

Many processes are sensitive to mist, such as painting. A few are sensitive to vapor, such as breathing air. A good example is oil mist and oil vapor. A common misconception is that the oil mist in compressed air is solely generated from the oil in the compressor, and that using an "oil free" compressor will give you oil free air. While an oil-lubricated compressor will have a small amount of oil carryover, there is already a higher hydrocarbon concentration in the air around us and, if you want oil-free air, you must filter that out even with an "oil-free" compressor.

An oil-lubricated compressor that is well maintained will pass hydrocarbons downstream in the amount of 1-3 parts per million (ppm). However, in relatively clean atmospheric air, there is already 6-10 ppm of hydrocarbons. If you're near a well-traveled road, an airport, or an industrial area, then the air will average 10-30 ppm of hydrocarbons in the air. You're breathing that in right now as you're reading this.

So remember, it's not the compressor that gives you oil-free air or even clean air. The filtration after the compressor gives you clean air; nothing else does. The junkiest, nastiest compressor that's passing a lot of oil, with just a moderate amount of filtration, will give you cleaner and dryer air than the most pristine "oil-free" compressor with no filtration. Also if you put that same exact moderate amount of filtration after the pristine compressor, the quality of air will be the exact same as the quality of air after the junky compressor.

Filtration for vapors and mists will have a micron, ppm rating, or an ISO rating. The manufacturer of your equipment will usually specify a micron rating and they should specify whether that applies to particulates, mist, vapor or all three. If it's a real concern to the equipment, they should specify an ISO rating.

ISO 8573.1:2010

ISO is the International Organization for Standardization. They publish standards about many different things in all different types of industry. ISO 8573.1:2010 is the ISO standard about compressed air quality. There are actually other parts to this standard and there is another standard that has to do with how the air and filters are tested. However, when you buy filters ISO 8573.1:2010 is what you need to look at.

There are three parts to this standard: Particulates, Water, and Oil:

The ISO rating will have 3 digits with a period between each number. Let's look at a common ISO rating: 2.4.2.

The first "2" represents the particulate requirement. It basically means a .1 micron filter. The chart above shows you how many particles are allowed to pass by of different sizes.

The "4" represents the water requirement. This is the simplest one. 4 means you need a dew point o 38F (or 3C). A properly sized refrigerated dryer will meet this standard.

The last "2" represents oil. Now this one is the trickiest....sometimes manufacturers need you to meet only the oil mist standard and not the oil vapor standard. An oil mist filter is different from an oil vapor filter. For breathing air and medical air you need to meet the complete standard (mist and vapor). For painting you'd only need to meet the mist standard.

Beyond ISO Ratings

Some processes require filters that go beyond the above ratings. There are even compressed air filters that are designed to filter out bacteria. Going into the "other" category is beyond the scope of this post. 99% of you reading this will never need or even encounter that level of filtration.

FILTRATION ORDER

If you're going beyond just standard shop air, you'll need more than one filter. You can't just stick an ISO 1 oil vapor filter in line and call it a day. A filter that gets out oil mist is different from one that filters out water, and they're both different from one that takes out oil vapor. An oil vapor filter will be ruined if it gets wet. A oil mist filter (a coalescer or coalescing filter) will get won't work properly if used to catch water.

The basic order is:

1. Catch the big particulates.

2. Filter out the water (can sometimes be combined with #1 above in the same filter)

3. Catch the smaller particulates and mists (if needed).

4. Filter out the vapors (if needed).

5. Bacterial filter (if needed).

The exception is if you have a desiccant dryer or a membrane dryer. Those dryers will filter out the water, but if any oil gets on the desiccant or membranes, it will ruin it. If you have a desiccant or membrane dryer, then order is this:

1. Filter to catch big particulates and most of the water.

2. Coalescing filter

3. Desiccant or membrane dryer to lower the dew point.

4. If you have a desiccant dryer, after it you need a particulate filter to catch the desiccant dust.

5. Vapor filter (if needed).

6. Bacterial filter (if needed).

You have to gradually step up the filtration as you go down the line. The filters that catch the smaller particles will get destroyed or clogged up by bigger particles or water. Thing of trying to catch cannonballs with butterfly net - it won't work. Catch the bigger particles first (the cannonballs), then catch some of the medium sized ones (basketballs maybe?), and then you can catch the small ones (your butterflies).

Consult an Expert

If you need advance filtration you need to talk to your local compressed air salesperson. If you just have shop tools, most of the time you can just stick in a water filter and go. However once you go beyond that, it gets complicated. There is a wide variety of filters available for you to buy. Even sizing filters is not always simple.

Just like the dryers we looked at in the last post, filters have correction factors, and you must take those into consideration when sizing them up. You can get your compressed air thousands of times cleaner than the air you breathe, and you can dry your air well beyond the driest any desert on earth has ever been. However, excessive filtration causes large pressure drop, additional maintenance, and greater energy costs. It's not recommended to go far beyond the level you need; you'd just be wasting your money and running up your electricity bill.

Your local compressed air salesperson should have hours of training and years of experience on filtration. They'll take into account the level of filtration you need, the flow you need it at, the correction factors based on the ambient conditions, the pipe size you have, and do all this while taking into account that you want to have the least amount of pressure drop possible. They should also take into account your duty cycle and maintenance considerations for later. Let them guide you toward the right decision.