Customer: I need a 100 CFM desiccant dryer.

Customer: I don't know, they just told me to get a 100 CFM desiccant dyer.

Me: Well, we have about 20 different ones that will do that. Did the person who's sizing it take into account purge air for a heatless version or maybe the high temperature from a heated one?

Customer: I don't know, just quote me on whatever one you think is best.

.........We'll stop there for now and look at another situation.........

|

| Not really concerned about your energy costs |

Now imagine that you walk into a car dealership.

You: I need a vehicle that goes 100 miles per hour.

Car Salesman: Well, that's pretty much any car or truck we sell. Can you be more specific? What are you looking for?

You: I don't know, just sell me whatever one you think is best.

Car Salesman: $$$$$$!

..........

There's not a lot of difference in the two conversations. However, the first one happens all the time, but the second (hopefully) never happens. Why?

Cars are an integral part to our lives and culture here in the USA. Your basic consumer is extremely educated on the ins and outs of cars. They've grown up with them, talked about them, and rode in them all their lives. Yes there are exceptions to this, but for the most part it's true for consumers in the USA - they know a lot about cars, compared to other machines with a similar amount of engineering and moving parts.

In the same manner, air compressed air is integral to millions of business, but our basic customer knows very little about them. Again, there are exceptions; we often have customers that are very educated about them.

Desiccant dryers are a specialized component in a compressed air system, which makes knowledge about them even less common. Even many people in the compressed air industry don't fully understand the different technologies of desiccant dryers and the true costs associated with each type.

Desiccant dryers can have a very small initial cost, but can often run up your electrical bill by thousands of dollars - sometimes tens of thousands. If you don't plan and configure air system correctly, it is an easy trap to fall into.

In the compressed air world, a desiccant dryer is machine uses desiccant beads to adsorb the water in compressed air. These beads draw the water out of the air using molecular adhesion. The beads are porous - they have pores so the water gets stuck to them inside and out. They don't react with the water, so if only clean air and water is contacting them, you don't have to replace the desiccant, you only have to regenerate it. Eventually it does get contaminated so the water particles don't stick to it, requiring replacement, but that should take years.

What contaminates the desiccant?

Compressor lubricant is the main culprit that contaminates desiccant. If you get oil droplets on the desiccant, it forms a film over the desiccant beads, rendering them unable to adsorb desiccant. That is the reason you see filters in front of a desiccant dryer. A coalescing filter catches the oil droplets, but before that you often need a particulate filter to protect the coalescing filter. After the dryer, you need another particulate filter to catch desiccant dust. You'll usually see three or more filters around a desiccant dryer - two before and one after. Sometimes a fourth filter, an oil vapor removing carbon filter, can be added for higher purity applications.

Regenerating desiccant - the key.

Desiccant dryers are all about how they regenerate the desiccant. What does that mean?

Desiccant can only adsorb so much water before it becomes saturated. Regeneration is just getting the water off the desiccant so it can catch more water. You have to either blow air on it or heat it - sometimes both at the same time. We'll go over each type of desiccant dryer and how it regenerates the desiccant.

Why would I need a desiccant dryer?

This is simple - you need a desiccant dryer if a dew point of below 35F is required for your compressed air. Anything else, you can use a refrigerated dryer, which would usually be more energy efficient and cost less to maintenance. We'll save the discussion about what dew point you need for a different blog post, as that is a long discussion.

We always ask customers "Why do you need a desiccant dryer?" Often the customer doesn't know. They've just been told to get one by the equipment manufacturer or it was engineered into a generic specification. It's important that you ask that question, because owning one is very expensive.

So let's go over the different types.

These are the simplest types of desiccant dryers. They are usually small and just hang on the pipe. They're filled with silica gel desiccant. That desiccant will change colors when fully saturated. When it's fully saturated, you can either replace it or cook it.

Yes, you put the desiccant in the oven and bake for 4 hours at 250F, or until the beads change back to their original color.

| |

| Mmm, mmm.. Just like Mama used to make! |

You can do this until they go bad from contamination, and then you have to replace the desiccant.

These dryers do not give a constant dew point, and they're usually for small operations. They start off with a lower dew point, and then as the desiccant gets more and more saturated, the dew point raises. The dew point from the beginning is determined by the inlet temperature.

You'll see these type of dryers for small paint booths. They're good for small operations that need a dew point below 37F. Other than the small pressure drop across the dryer and associated filters, there is no energy cost involved, other than the power you use for the oven to cook the beads.

These dryers are limited in size, so for larger applications, you have to use something else, but they're nice and easy for small installations, as long as you keep an eye on the desiccant.

Pros: Inexpensive, easy to install, no purge air.

Cons: Limited to small installations, short time between desiccant changing (or cooking)

Heatless Twin-Tower Desiccant Dryers

These are by far the most common desiccant dryers we see in the industrial compressed air world. When a customer says they want a desiccant dryer, this is usually what they mean.

These are the most common simply because this type of desiccant dryer is the least expensive, and has been around the longest. They are simple to understand and operate, as well.

However, when we say that a desiccant dryer can cost you thousands on the electricity bill, this is the culprit. While compared to most desiccant dryers, they are less expensive up-front, they end up being way more expensive, because of their (not so) hidden demon....purge air.

|

| Run for your lives! It's PURGE AIR!! |

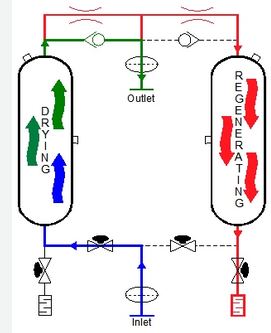

Purge air is how this type of dryer regenerates its desiccant. There are two towers, but only one is drying air. The other is either sitting idle or regenerating. The tower that is regenerating has compressed air running through it and blowing out to atmosphere.

The compressed air used is 10-15% of the dryers rated CFM. That means if you have a 100 CFM dryer, then 10 to 15 CFM of the compressed air your compressor is being used for purge air.

So basically you create a huge leak to regenerate the desiccant. We've talked about how expensive leaks are in a previous post.

|

| I felt like this while telling them the cost of purge air. |

We had one case where the customer wanted a 600 SCFM desiccant dryer to run 24/7, and their energy cost was about 40 cents per kWh. We did the energy calculations for the different types of desiccant dryers. With this type of dryer, the purge air would have cost them over $1,000,000 in wasted electricity over the course of 10 years.

Yes, that is an extreme case, but seeing tens of thousands of dollars of electricity being wasted for purge air is not uncommon in large factories with desiccant dryers.

Pros: Inexpensive.

Cons: Purge air - a lot of it. They run up your electric bill by a large amount.

Purge Saver Option:

Not all of these dryers waste 10-15% of the dryer's CFM as purge air. You can buy them with a purge saver option. The purge saver reduces the amount of purge air by either sensing the dew point of the regenerating tower. There are various ways to do this, and we won't go into them here, but a purge saver can lower the purge air by 2-3%. In most cases the extra purge saver costs will pay for itself because of the electricity it will save.

Pros: If you go with a heatless dryer, you should get this option as it will save electricity.

Cons: Adds a little to the initial cost.

Heated Desiccant Dryers

These dryers not only blow air across the desiccant to dry it, but they heat the desiccant while doing this. They have a heating element that gets the air extremely hot before it hits the desiccant. They can use much less air, because the heat helps to cook off some of the liquid water. Hot air can also hold more moisture. They can be internally or externally heated.

By doing this they reduce the amount of purge to about 7% of the rated CFM of the dryer. This is usually thousands of dollars worth of savings in electricity for large factories, compared to the heatless desiccant dryer. Generating compressed air is very expensive, so the cost of running a heating element is minimal in comparison.

They cost about 50% more, but the return on investment is usually less than two years.This sounds great, but just like before it has its own hidden demon.....

|

| Typical discharge temp of a heated desiccant dryer |

When they called these "heated," they weren't kidding. The discharge temperature of a heated desiccant dryer is 350F to 450F. That's the temperature of the compressed air going downstream toward your equipment. They have to use specialized high temperature filters after heated desiccant dryers. They're usually included with the dryer, so you don't have to normally worry about that part.

However, you do have to account for the heat. Not only can it fry sensitive equipment that might be downstream, but the pipes have to be insulated, and the dryer has to be insulated. It will cause severe burns on any personnel contacting pipe or tank that is over 300F. Also don't forget that the pressure ratings of pipe and fittings are determined by the temperature (we talk about it here). So that needs to be looked at, too.

This can all be easily accounted for by having a decent length of pipe after the dryer where the air can cool down. Additionally the dryer will often come with the insulation for its own tanks. However, you can't just grab one of these out of factory stock without planning for all of the above. Many customers are unaware of this, along with many engineers that specify jobs that include these.

Pros: Much less purge air than heatless, so the hit on your electrical costs isn't too bad.

Cons: Higher initial cost, extremely hot discharge air, requires extra personnel safety.

Heated Blower Purge Desiccant Dryer

So in comes a technology that we mentioned previously, the side channel blower. Using a small side channel blower to make the purge air turns out to be much less expensive than using air from your air compressor.

Just like the heated desiccant dryer, the air is also heated. So this is nearly identical to it, other than it adds a small side channel blower to provide the purge air. Just like the example above, the discharge of this dryer is 350F-450F.

|

| This little blower can save a lot of money |

This dryer still can use a little bit of the air from the main compressor as purge, when needed. However, that can be as low as 0.7%.

These dryers are typically double the price of the heatless desiccant dryers and about 15-20% more than the internally heated desiccant dryers. However, they are nearly always worth the extra investment.

These dryers are typically double the price of the heatless desiccant dryers and about 15-20% more than the internally heated desiccant dryers. However, they are nearly always worth the extra investment.

Pros: Very energy efficient compared to other desiccant dryers.

Cons: Initial cost is very high, extremely hot discharge air, requires extra personnel safety.

Heat of Compression Dryer

This is a dryer that is used for a special situation. It works extremely well in that situation, but not in any other. The situation is that you have a non-lubricated rotary screw compressor with no aftercooler (or the aftercooler is bypassed).

This is a dryer that is used for a special situation. It works extremely well in that situation, but not in any other. The situation is that you have a non-lubricated rotary screw compressor with no aftercooler (or the aftercooler is bypassed). In that situation the air coming out of the air compressor is 350F-450F. Sounds familiar right? Additionally there's no compressor lubricant to contaminate the desiccant.

So they take the hot discharge from a non-lubricated rotary screw compressor and run it directly into the tower that is regenerating first. Then the air runs through the other tower to be dried. Depending on the temperature of the air coming out of the compressor, sometimes a heater is used to boost up the temperature, and sometimes a side-channel blower is used to assist. It make take a while for the compressor to get that hot.

There is also another version that uses a rotating drum, instead of two towers, but the concept is the same - the hot air from the compressor is used to regenerate desiccant first, and then it's dried immediately after by the non-saturated desiccant.

These dryer use no purge air. They are very energy efficient, often using no more electricity than a toaster. They are very expensive initially, but there unless you're getting free electricity, there's almost no case where they won't pay for the extra cost with electrical savings. Additionally the air is usually ran through a heat exchanger in between the towers, so the air is cooled, too. Therefore you don't have the extremely hot air coming out of it, like you would with a heated dryer.

However, again, they only work well in a very specific situation. If you're not in that situation, they're usually not the right choice.

Pros: In the right situation, it's extremely energy efficient.

Cons: Very expensive initial cost, only suitable for one very specific situation.

Single Tower Blower Purge Dryer

|

At the end of this cycle, just like the heated blower purge dryer, it uses a heating element and a small side-channel blower to regenerate the desiccant. It takes 4-8 hours to fully regenerate it, and they usually have a sensor to turn off the regeneration cycle when it's done.

These dryers are extremely energy efficient, compared to the other desiccant dryers. They also use very few moving parts, which makes them very durable and easy to troubleshoot. They do have one drawback - you can't use them in a 24/7 production. However, you can use two of them together for a 24/7 situation. It increases the initial cost greatly, but it's often worth it for the energy savings.

Pros: The most efficient desiccant dryer - sometimes even more efficient than a refrigerated dryer. Very few moving parts.

Cons: Cannot be used in a 24/7 process unless you double-up on them. Only a few manufacturers make them, so hard to find (we sell them!).

Combination Desiccant/Refrigerated Dryer

From one of the most simple, we go to the most complicated. A refrigerated dryer is placed before a desiccant dryer. The reason why you would do this is that usually running a refrigerated dryer is less expensive that the electricity to produce the purge air from a desiccant dryer. The desiccant dryer is a a heated blower purge.

Where this type of dryer is the best is a case is when you only need a dew point that is 40F or above for your process, but you have temperatures that get below 40F. So when it's hot the dryer will run and the desiccant won't be involved, Only when it gets cold will the desiccant dryer operate.

Even when you need a lower dew point, this dryer is still very energy efficient, sometimes the most efficient out of the desiccant dryers for your situation. Not only is the electricity to run the refrigerated dryer usually less than the electricity to produce the purge air, but much less moisture is going to the desiccant, so it can go longer between purge cycles, which saves more electricity. Additionally, because there is less adsorbing and purging cycles, the desiccant will last much longer. So instead of changing out the desiccant about every 5 years, it's about every 10 years. That is a significant maintenance savings.

These dryers are four to six times the initial price of a heatless desiccant dryer of the same approximate CFM. However, every time we have quoted one, the return on investment was less than two years. They take up a lot of floor space, and are very complicated, but in the right situation, they'll save you a lot of money on both electricity and maintenance.

Pros: Very energy efficient, desiccant can last 10 years, built in redudany if you don't need a low dew point.

Cons: Very, very expensive initial cost; takes up lots of floor space, complicated.

So What Dryer is Best For Our Installation?

I'm sorry, but I have to tell you the same thing I tell my kids about school - you have to do you homework. If you just pick out an inexpensive heatless dryer without looking at the energy costs, you'll probably lose thousands of dollars later.

First ask yourself - Do I really need a desiccant dryer? Whoever said you need one, ask them why, if you don't know already.

Second, once it has been established that you really do need one, find out how many hours you run per year, your electrical cost (kWh), and what dew point you need.

Next figure out the initial cost of each dryer, what the maintenance cost of each dryer is, and how much electricity it will cost to run each dryer (including the purge air from your compressor). If you don't know how to figure this out, ask your local compressed air salesperson. He or she will have a spreadsheet that does this automatically or will have the equations.

Look at the total cost of the dryer after two years, five years, and ten years, and then decide what's best for your company. You will see that often the dryer with the least expensive initial cost is usually more expensive after a year or two. Nearly always when you have over 300 SCFM of compressed air that needs a low dew point (below 35F), buying the dryer with the least expensive initial cost will lose you thousands later. This doesn't normally take more than a day's worth of research.

Don't forget to maintain your dryer.

Your desiccant dryer will have pre-filters and after-filters. You must change the elements in them on a regular basis, especially the pre-filters. The pre-filters keep your desiccant from getting contaminated. Changing the desiccant is an expensive and labor intensive process.

Your desiccant dryer will have pre-filters and after-filters. You must change the elements in them on a regular basis, especially the pre-filters. The pre-filters keep your desiccant from getting contaminated. Changing the desiccant is an expensive and labor intensive process.Additionally keeping the elements changed regularly will reduce the pressure drop across them. More information about why this is important is here.

It would be a waste to buy a more expensive dryer, because it costs less to operate, and then lose those savings because you didn't do the maintenance. Even with the cheap one, doing the appropriate maintenance is time save money in the long run.

Questions?

Questions?

Picking out the right desiccant dryer can be confusing process - there are so many different variables that you have to account for. Remember your local compressed air house should have a salesperson or technician that has been trained on sizing them correctly. Make sure they're asking the right questions and you are giving the correct answers. If you're not sure, you can always call us.

We'd be happy to help. We offer all of the dryers mentioned above, and we have professional, factory-trained personnel that know how to size them correctly and account for energy costs.

No comments:

Post a Comment